The Ezinex® and the Indutec Technologies

Engitec Technologies S.p.A. supplies industrial plants throughout the world, offering its services from the definition of the technology up to the turn-key construction, start-up, commissioning and taking over by the client.

Engitec is very active in the technologies innovation, specially in the field of hydrometallurgy and electrolysis for the production of metals. Its Ezinex, Flubor and Ecuprex processes are the most revolutionary approaches to the extraction and production of Zinc, Lead and Copper of the last twenty years.

These innovative technologies have been developed by Engitec technical researchers from the invention phase up to the industrial pilot plant.

The Ezinex® Process

EZINEX®, an acronym derived from “Engitec Zinc Extraction”, was developed by Engitec in Italy since 1993.

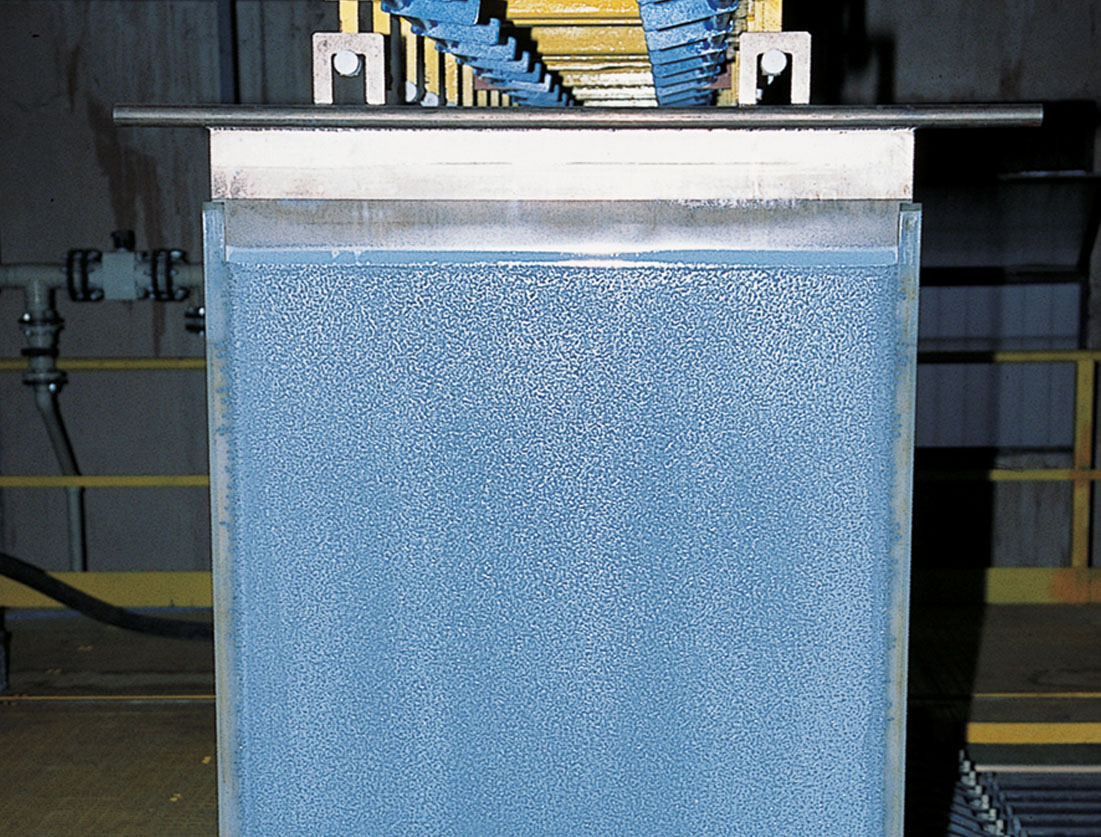

The basis of the process is a unique hydrometallurgical zinc recovery system that is not sensitive to the typical impurities affecting traditional zinc production. Engitec’s R&D team successfully tested zinc-containing materials from various sources including electric arc furnace (EAF) dust from steel works, Waeltz oxides, oxides from converters and zinc ashes.

The Indutec Process

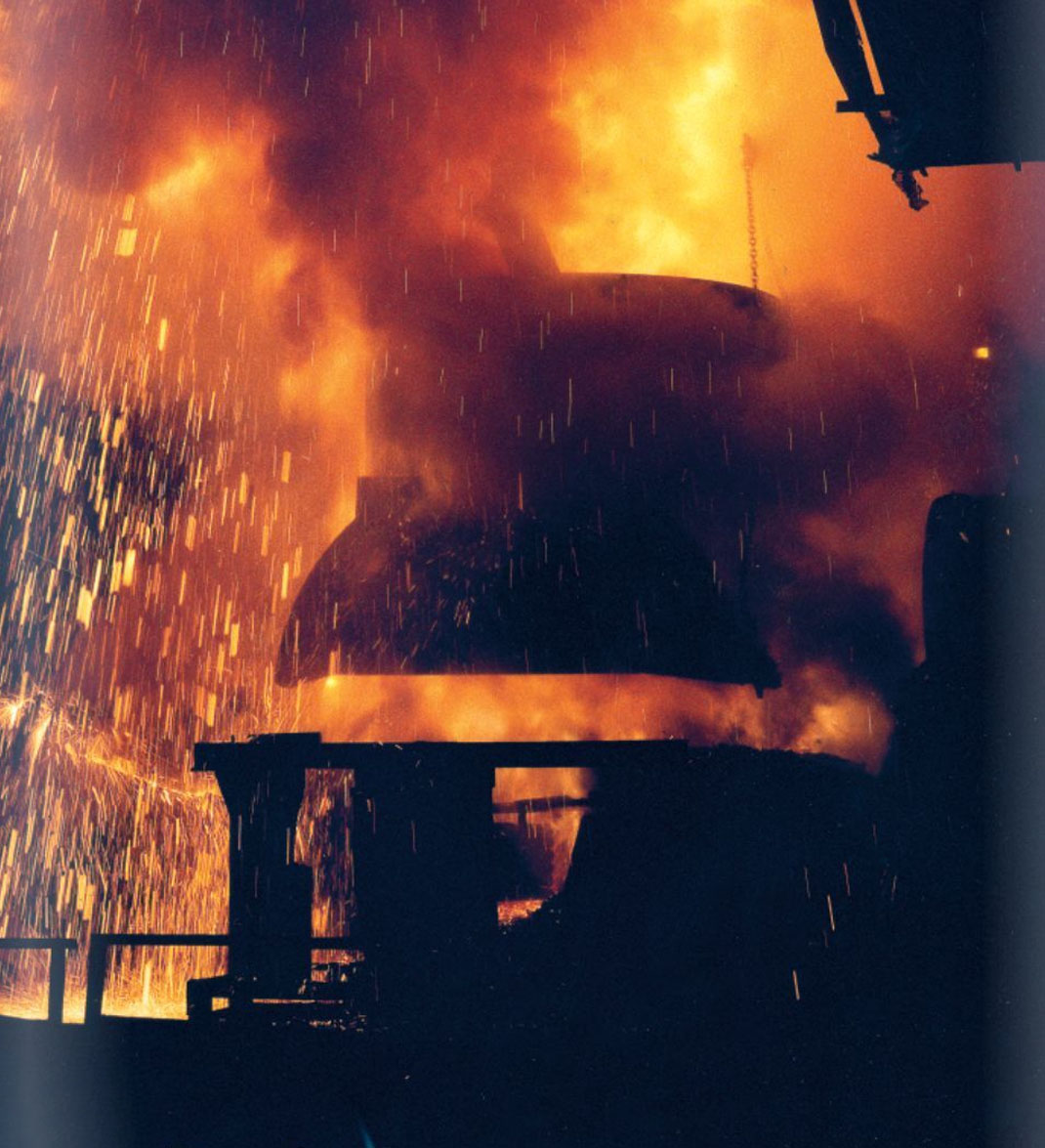

The INDUTEC Process is design to treat EAFD and oxidized zinc bearing materials with high Fe content. The INDUTEC Process is based on a low frequency “coreless” induction furnace where the zinc bearing material is appropriately fed with coal and slagging additives. The following results are achieved:

- the reduction of iron oxide to pig iron

- the concentration of zinc and other heavy metals into the fumes leaving the furnace

- the formation of a glassy inert slag

The pig iron bath, kept at the right process temperature and vigorously stirred by the inductive current, is the reducing phase of the process where the heavy meal oxides fed to the furnace are reduced to metal.

The liquid slag covering the pig iron molten bath is the oxidizing phase of the process where carbon is oxidized to CO while the metals, leaving the molten bath, are converted to oxides and vented out of the furnace by the gas phase.

A gas filtration unit provides the separation of solids from the gas stream leading to the recovery of a metal oxide mix and the high zinc concentration crude zinc oxide. The final concentration of zinc strongly depends on the composition of the feed.