...Golden Profit from

exhaust lead acid

batteries through

Engitec Technology

and Equipment

Engitec provides the full range of equipment

for lead-acid batteries scrap processing and for lead production.

Equipment details for lead recycling can be

found in the attached documents.

- CX BREAKER EQUIPMENT

- SMELTING EQUIPMENT

- REFINERY EQUIPMENT

- LEAD CASTING MACHINES

- FILTRATION SYSTEM

Through Engitec Equipment and Technology

The lead battery recycling

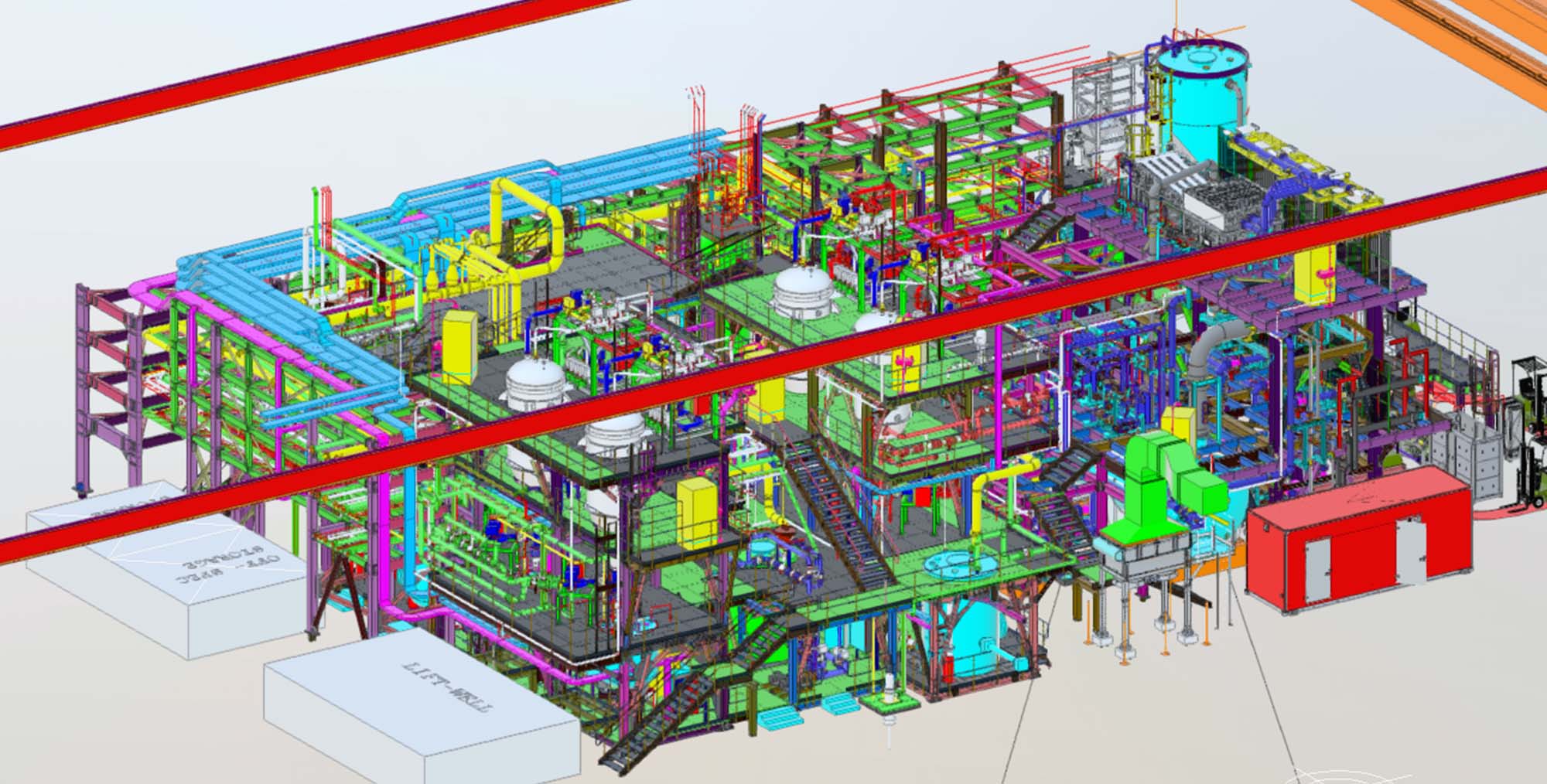

Engitec Technologies S.p.A. supplies industrial plants throughout the world, offering its services from the definition of the technology up to the turn-key construction, start-up, commissioning and taking over by the client.

Engitec is very active in the technologies innovation, specially in the field of hydrometallurgy and electrolysis for the production of metals. Its Ezinex, Flubor and Ecuprex processes are the most revolutionary approaches to the extraction and production of Zinc, Lead and Copper of the last twenty years.

These innovative technologies have been developed by Engitec technical researchers from the invention phase up to the industrial pilot plant.

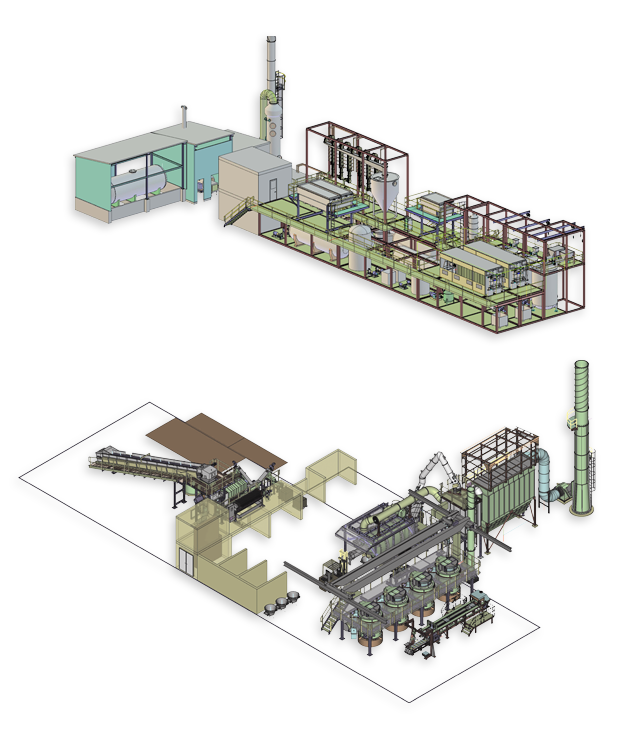

The battery recycling system

The battery recycling system can be composed as follows:

The electrolyte drained from scrap batteries is collected and filtered to remove the solids and stored for other use. It can be neutralized or processed within the paste desulphurization unit.

The negative pressure inside the kiln is maintained on the pre-set value by a special regulating dumper placed at the process gas refractory lined outlet duct. After the dumper the process gas are blended with the sanitary air captured by the relevant hoods, to be sent to the dedusting bag house filter.

The grids melter is enclosed by an hoods system, and the captured exhausts gas and sanitary air are sent to bag house filtration system for dedusting; the entrained flue dust is collected into a dedicate sealed box and sent to the main rotary furnaces for recovering of the metal contained.