Inspiring Innovation:

the Company

Engitec know-how and expertise has been consolidated and improved through the design, manufacturing and servicing of Plants dislocated in more than 40 countries in the 5 continents.

Mission

Vision

To be always a strategic provider of recycling solutions for the market while being an exciting company in which to grow, recognized for our innovative spirit and leadership in recycling and in the development of new processes.

Innovation

Technology

During a project development Engitec Research Center operates in combination with engineers from the Process Department for the examination of the Client’s input and determination of the output figures for the definition of the best applicable technology for the scope.

…there is no today

without yesterday…

Engitec was established in 1978 when a group of brilliant and foresight Engineers operated the spinoff from the Mother Company. No doubt it has been a long way to that started between the two wars….

The Mother Company started, in the neighborhood of Milan (Italy), its industrial activities based in collection, classification and processing of non-ferrous metals. Incidentally, the Mother Company became one of the largest and most important international metallurgical company worldwide between the 50s’and the 60s’.

The Mother Company designed, manufactured and tested the first plant for the recovery of lead/acid batteries. This plant was characterized by manual crushing and smelting of “plates” in reverberatory furnace.

The Mother Company made and started the first lead electrolysis.

It was designed and developed the first mechanized system, to crush and separate the batteries, mainly with ebonite cases, inside a rotary drum, with the separations by rotating screens and by sink and float system.

Engitec, standing for Engineering & Technology is established as spin-off of from the Mother Company.

It was the time for a new concept of batteries processing through crushing by hammer mill, separation of paste by screening and separation by hydrodynamic action. Designed, tested and installed by the same team of technician and other specialists that operated the spinoff.

First development of mechanized wet-process battery breaker.

The birth of the new technologies.

The Engitec R&D Company is established with the mission of exploring innovative technologies.

The first plant for Aluminium salt slag processing (STE) is installed and operated.

The first pilot plant for lead concentrate electrowinning process (FLUBOR) is positively tested and patented.

The first plant for Zinc recovery from EAF Dust (EZINEX) is installed and operated.

The consolidation phases.

The process of desulphurization of the lead battery paste is tested and applied on several plants worldwide.

Engitec R&D Company is incorporated into Engitec Technologies creating the Engitec Research Center (ERC).

The new process of super-desulphurization of the lead battery paste is tested and applied.

The FLUBOR process is designed and installed as demonstrative plant at DOE RUN Co. (MO, USA).

The CX battery breaker plant reaches the number of 60 installations in the world.

The expansion phases.

Akrasun, a 4,4 MW photovoltaic power station, built and owned by Engitec Technologies, started operation.

A2L Energy, a cogeneration power plant built and owned by Engitec. Technologies for the supply of electric energy and steam to a North Italian paper mill, started operation.

Engitec technologies acquires 80% shares of the German company Richard Kablitz G.m.b.H., specialized in design and construction of energy production plants from biomass combustion.

GMS (Global Metallurgical Solutions) founded in 2014 is incorporated in Engitec Technologies.

Inspiring Innovation:

the Group

INSPIRING INNOVATION is the key Company Mission of Engitec, which is pursued daily by developing recycling technologies to enable efficiency and environmental compliance.

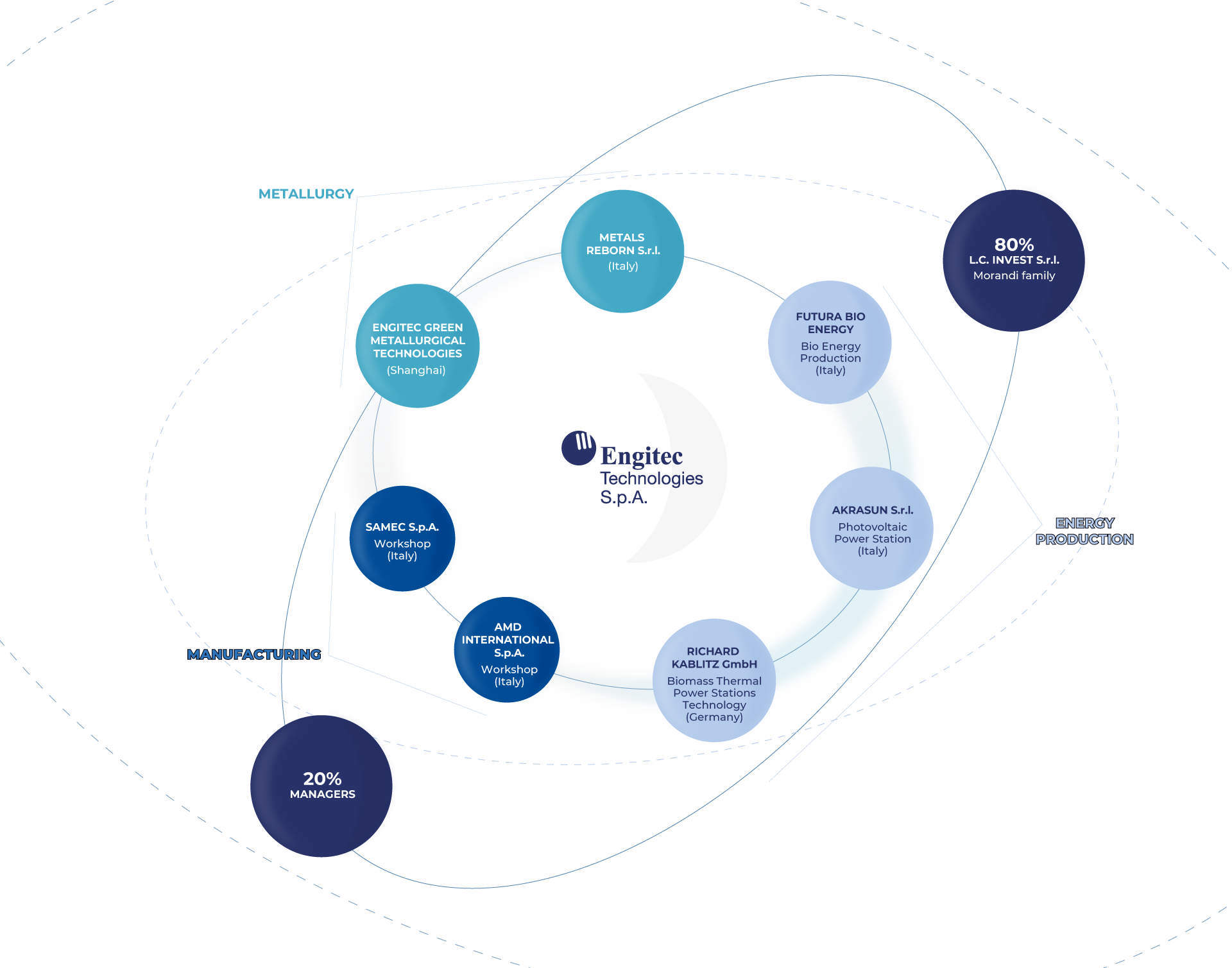

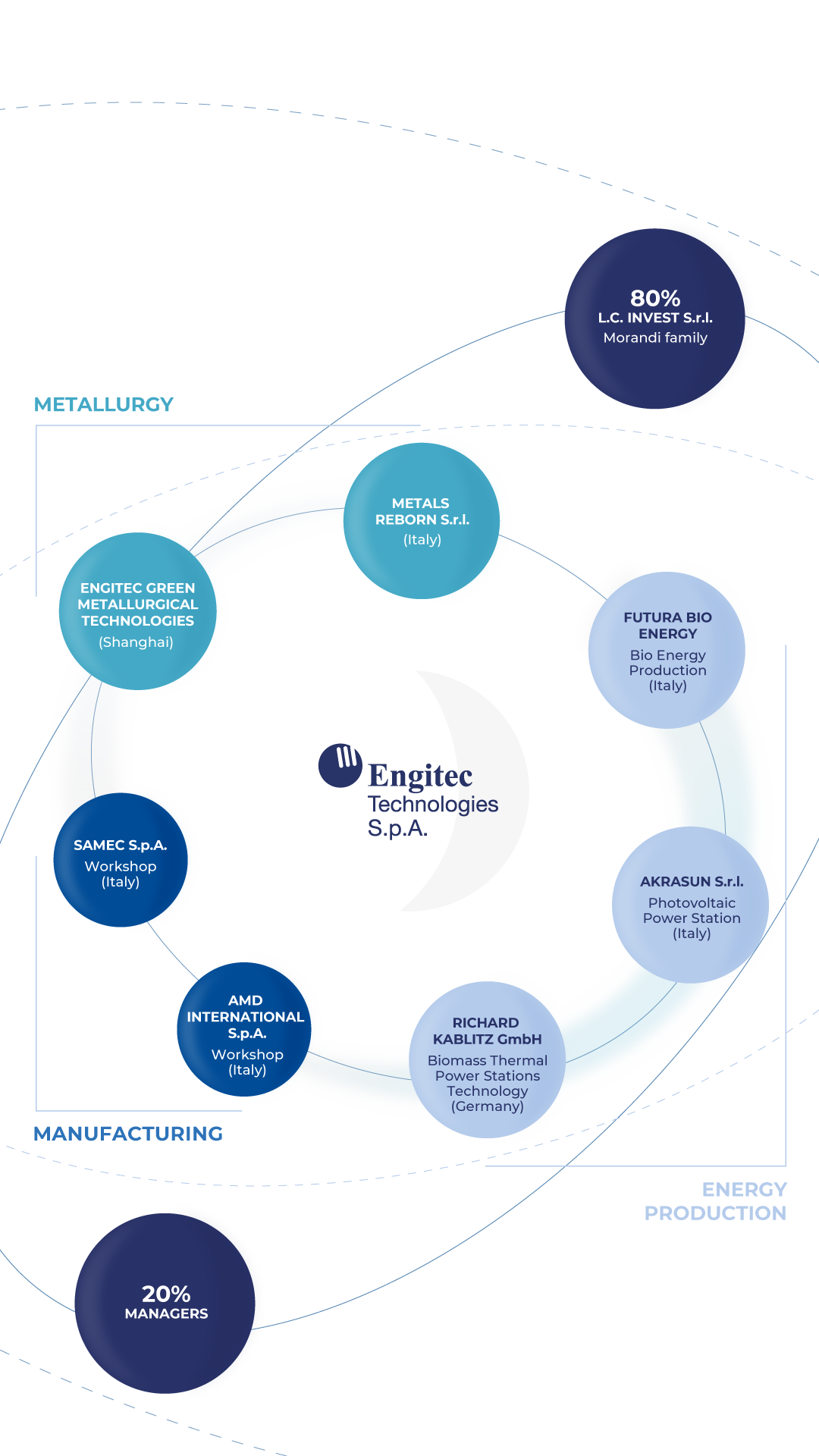

These Companies are part of Engitec Ecosystem in different sectors of activity:

Environmental,

Social, Governance.

ESG Approach

ENVIRONMENT AND SAFETY TASK

Safety first” has always been the mind set of Engitec for all the activities. In undertaking complex projects that often include social impacts, Engitec aims to achieve efficiency, innovation and results, paying maximum attention to life quality and the working standards. Every effort is made in order to direct its technology to cut both the environmental and the healthy impact through the reduction of wastes and emissions as well as always maintaining a safe and accident-free work environment.

SOCIAL CARE

Several actions in the social field have been carried on by Engitec, especially as activities in favor of childhood, both in Italy and in third Countries.

Engitec continues to leverage its social commitment through volunteering, employee donations and support to local and global non-profits organizations.